Free Courses Sale ends Soon, Get It Now

Free Courses Sale ends Soon, Get It Now

Disclaimer: Copyright infringement not intended.

Context

The Indian government is planning to replace metal with carbon fibre in some key manufactured components, namely in the aerospace, civil engineering and defence sectors. For this, it is considering to start manufacturing carbon fibre in the country.

Details

More on the news

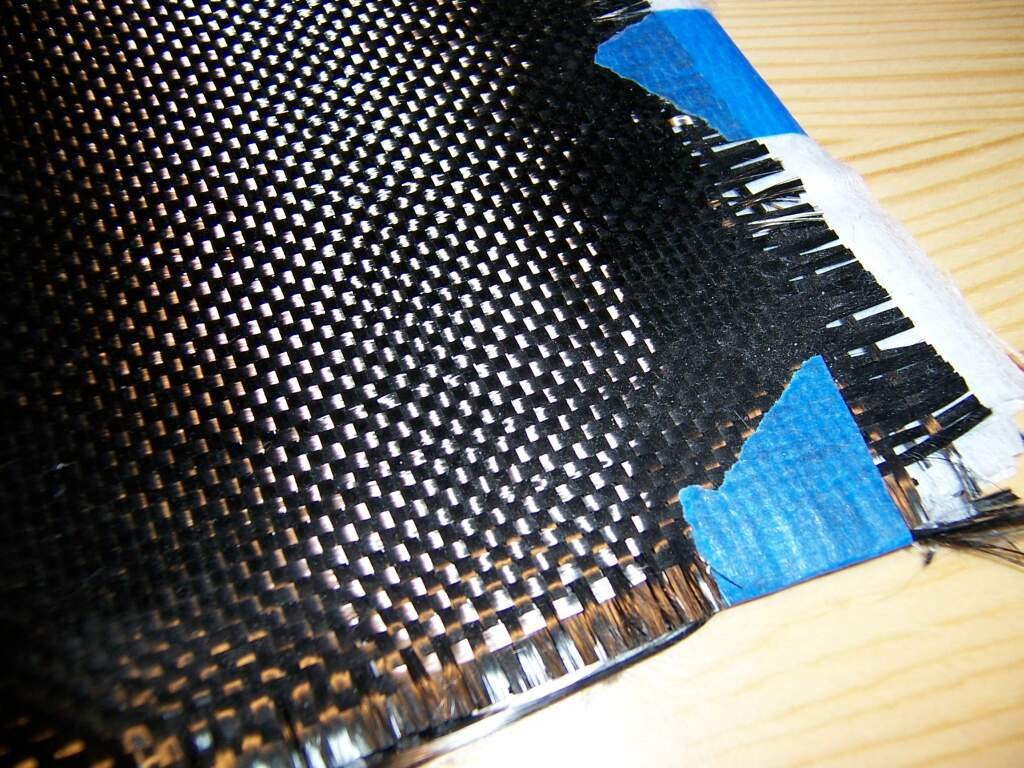

About Carbon Fibers

Manufacturing Process:

Properties of Carbon Fibers:

Types of Carbon Fibers:

Applications of Carbon Fibers:

Conclusion

Carbon fibers represent a versatile and high-performance material with diverse applications across industries. Ongoing research and technological advancements continue to expand the capabilities and potential applications of carbon fibers, driving innovation and sustainability in various sectors.

Must read articles:

Sources:

|

PRACTICE QUESTION Q. The Indian government's plan to start manufacturing carbon fiber is a significant development with several implications and benefits. Comment. (150 Words) |

© 2024 iasgyan. All right reserved