Free Courses Sale ends Soon, Get It Now

Free Courses Sale ends Soon, Get It Now

Disclaimer: Copyright infringement not intended.

Context

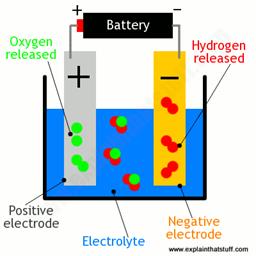

Electrolyzer

.jpg)

How does an Electrolyzer work?

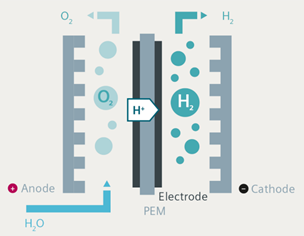

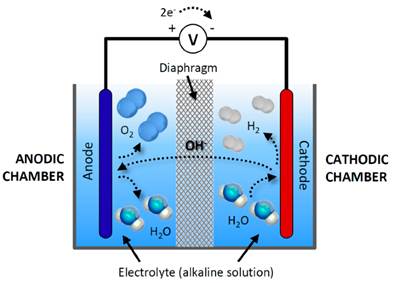

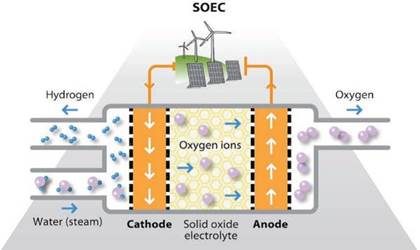

Types of Electrolyzers

India and Electrolysers

Present Scenario

Untapping the opportunity: Key Steps

Significance of Electrolysers

The way forward

Read all about Green Hydrogen: https://www.iasgyan.in/daily-current-affairs/green-hydrogen-47

© 2024 iasgyan. All right reserved