Free Courses Sale ends Soon, Get It Now

Free Courses Sale ends Soon, Get It Now

Copyright infringement not intended

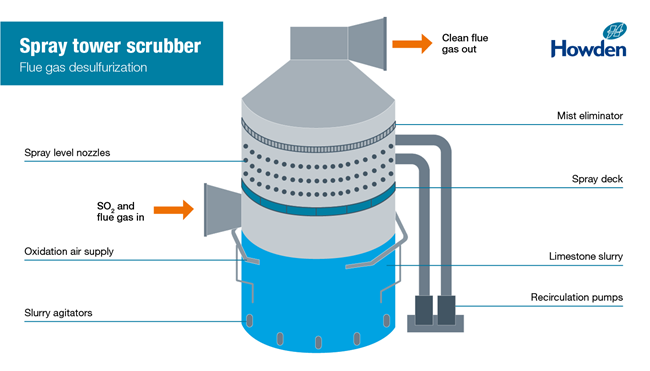

Picture Courtesy: https://www.howden.com/en-gb/articles/flue-gas-desulfurization-acid-rain

Context: Thermal power plants are required to install Flue Gas De-sulphurisation (FGD) equipment to adhere to emission regulations, as per the guidelines set by the Ministry of Environment.

Details

Emission Norms Compliance

Monitoring and Oversight

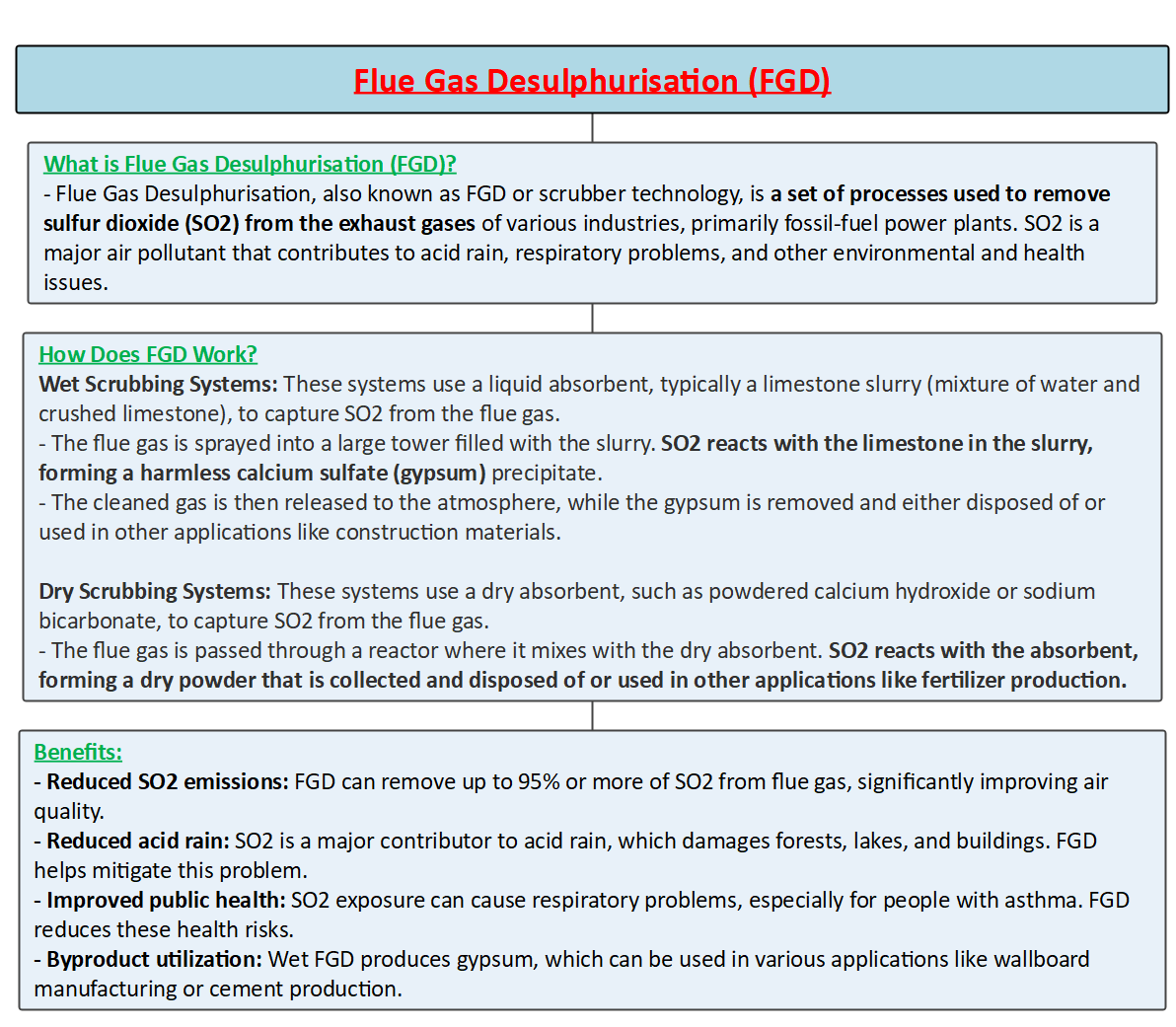

Flue Gas De-sulphurisation (FGD)

|

FGD is a process that uses a sorbent, usually lime or limestone, to react with SO2 in the flue gas and convert it into harmless products. The sorbent can be injected as a dry powder, sprayed as a wet slurry or circulated as a seawater solution. The reaction products can be collected as solid residues, dissolved in water or discharged into the sea. |

Why is FGD important?

Different types of FGD systems

Wet scrubbing

Spray-dry scrubbing

Wet sulphuric acid process

Dry sorbent injection

Conclusion

|

PRACTICE QUESTION Q. With carbon removal technologies still in their infancy, what are the ethical and feasibility concerns surrounding large-scale implementation of negative emissions strategies? To what extent can they be relied upon to compensate for continued emissions, and what role should they play in our climate mitigation strategy? |

© 2024 iasgyan. All right reserved