Free Courses Sale ends Soon, Get It Now

Free Courses Sale ends Soon, Get It Now

Disclaimer: No Copyright infringement intended.

Context

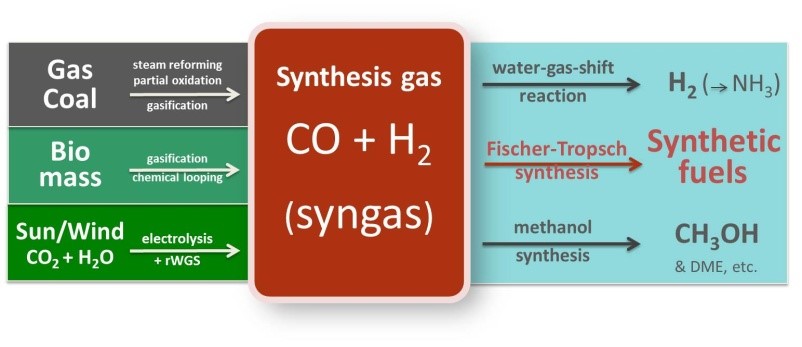

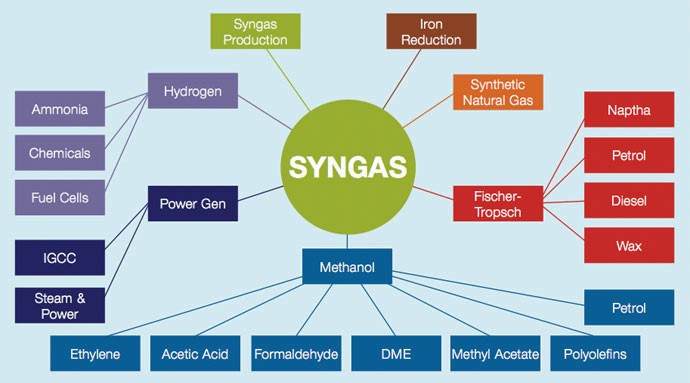

Gasification

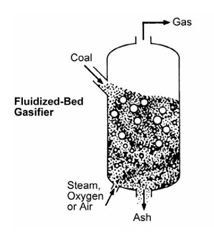

What is fluidized bed gasification?

|

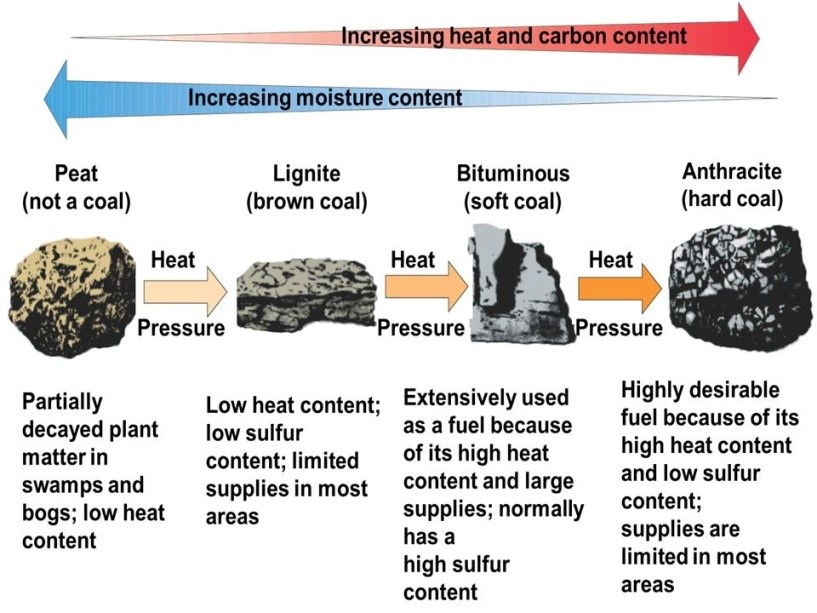

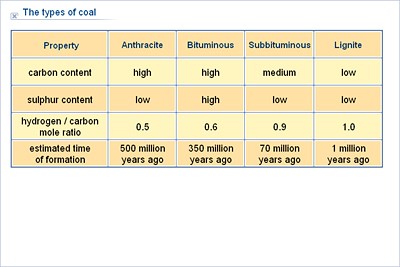

Types of Coal

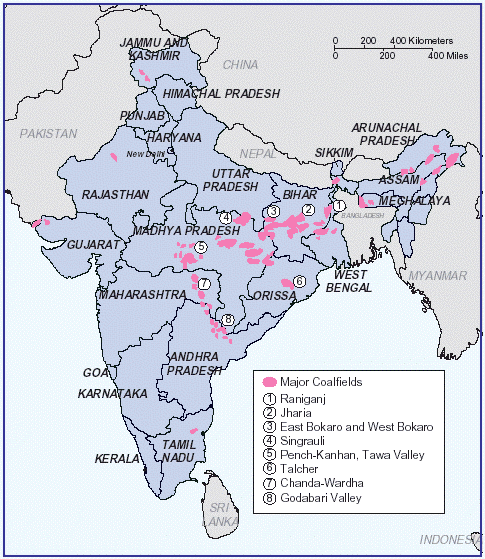

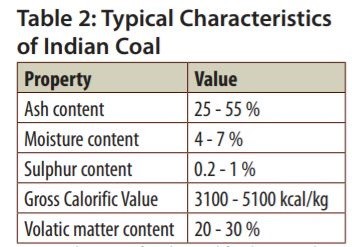

Coal in India: Key Pointers

https://pib.gov.in/PressReleasePage.aspx?PRID=1755768

© 2024 iasgyan. All right reserved