Disclaimer: No copyright infringement of images intended.

Context

- In the presence of Union Minister of Chemicals & Fertilizers, a practical field trial of Drone Spraying of Nano Liquid Urea was conducted in Bhavnagar, Gujarat.

- India has become the first country in the world to start commercial production of Nano Urea.

About

- Nano Urea is a nutrient to provide nitrogen to plants as an alternative to the conventional urea.

- Nano Urea Liquid can curtail the requirement of the same by at least 50%.

- Nano nitrogen (Nano Urea) can enhance farmer’s crop yields beside nitrogen saving to the extent of 50%.

Significance

- The excess conventional urea causes an environmental pollution, harms soil health, and making plant more susceptible for disease & insect infestation, delayed maturity of the crop & production loss.

- Nano Urea Liquid makes the crops stronger, healthy and protects them from lodging effect.

- It will lead to reduction in Global Warming

- It will improve the quality of underground water by polluting it less.

- It will cut down post harvesting costs and increase farmers’ income.

Benefits of Drone spraying

- Drones will be able to spray more land in less time. This will save the time of the farmers.

- The cost of spraying will be less. This will result in financial savings to the farmers.

- Along with this, the safety of the sprinklers will also be ensured.

|

Natural Urea

Urea is a waste product in the body with no physiological function. It dissolves in the kidney and blood before it is excreted as urine. The organic compound of Urea has two different NH2 groups that are connected by the carbonyl functional group. Urea is non-toxic, which is why it dissolves in water. Apart from being colorless, it also has no smell. It is found in milk, blood, and sweat of mammals

Urea was separated from urine by Hilaire Marin Rouelle, a French chemist back in 1773.

Later in 1828, Friedrich Wohler, a German chemist, started its official preparation from Ammonium Cyanate.

|

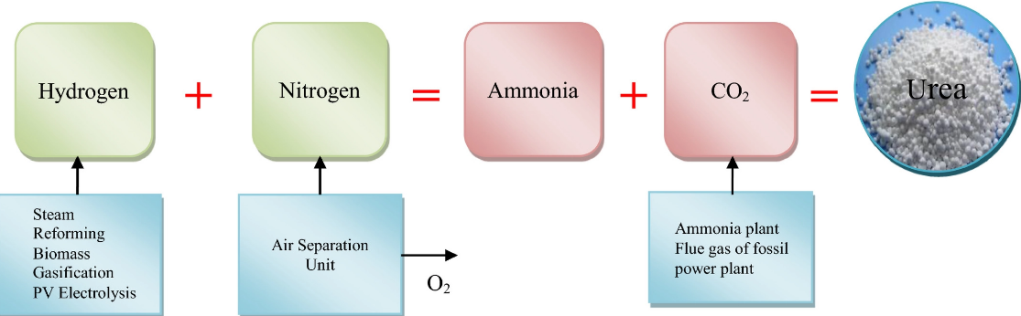

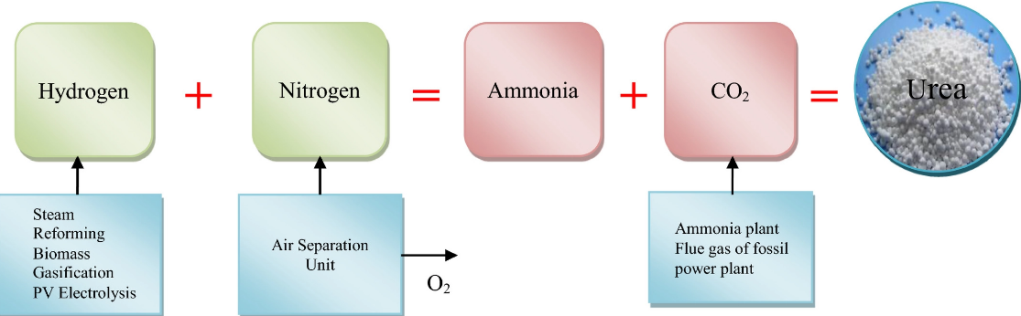

Conventional Artificial Urea

- Urea is a white crystalline organic chemical compound. It is the most important nitrogenous fertiliser in the country because of its high N content (46%N).

- Urea consists of Nitrogen, Carbon, and Oxygen. Formula: CH₄N₂O

- Besides its use in the crops, it is used as a cattle feed supplement to replace a part of protein requirements.

- It has also numerous industrial uses notably for production of plastics.

Uses of Urea

- As fertilizers as it increases the yield of crops

- As animal feed additive.

- as a cleaner; hair removal creams and dish soaps

- in the fermentation industry

- as a refrigerant

- neutralize pollutant

- in textile industries

- as a fuel for rocket engines

- manufacture of synthetic fibre like rayon and nylon

- in creams/ointments

- manufacturing melamine.

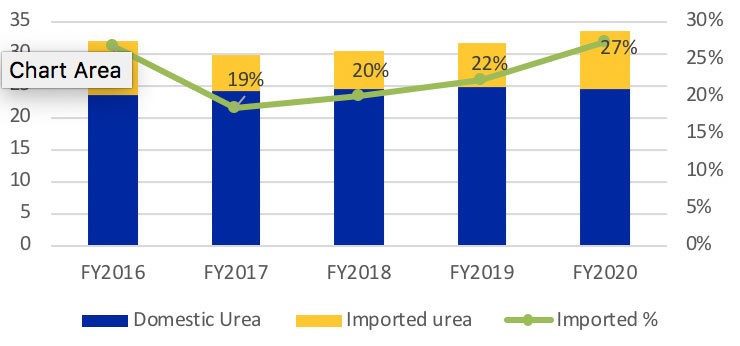

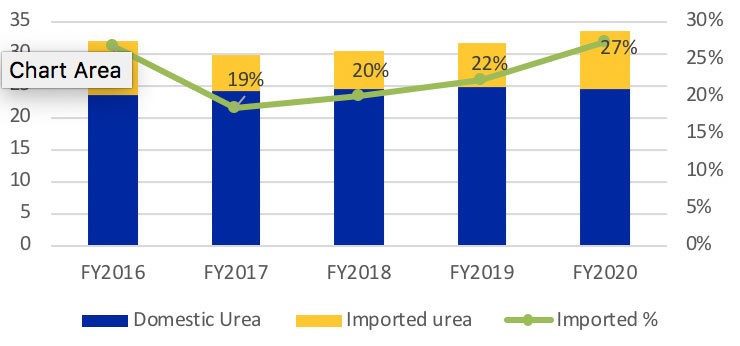

Production and Import

- India is the top country by urea production in the world.

- As of 2018, urea production in India was 23.9 million tonnes that accounts for 42% of the world's urea production.

- The top 5 countries (others are Indonesia, the United States of America, Canada, and Viet Nam) account for 81.22% of it.

- India’s import of urea rose 22 per cent to 91.23 lakh tonnes during the last fiscal year i.e 2019-2020.

The only regulated Fertilizer

- Urea is the only fertilizer at present with pricing and distribution being controlled statutorily by the Government.

- The Central Govt. pays subsidy on urea to fertiliser manufacturers on the basis of cost of production at each plant and the units are required to sell the fertilizer at the government-set Maximum Retail Price (MRP).

- Thus, no one can sell urea above the MRP declared by the Govt. Under the Concession Scheme, the MRP for each fertilizer is indicative in nature.

Advantages of Urea Fertilizer

- Highest nitrogen content. This percentage is much higher than other available nitrogenous fertilizers in the market.

- The cost of production of urea is relatively low.

- Not subject to fire or explosion hazards, so there is no risk in the storage of urea.

- Wide application. Urea fertilizer can be used for all types of crops and soils.

Issues plaguing the Urea Sector

- India’s Fertiliser industry is classified under the “red category” of polluting sectors by CPCB.

- Wastewater generated at urea plants contain ammoniacal and Kjeldahl nitrogen, and cyanides in varying concentrations.

- This leads to water-pollution problems.

- The sample of groundwater and effluents tested in the laboratory has high levels of contaminants (way above permissible limits) - Centre for Science and Environment’s innovative Green Rating Project (GRP) Report.

- Using urea excessively on crops causes adverse effect on soil, crop quality and overall eco-system besides leading to pest and insect attacks.

- Too much Urea damages plants: nitrogen impairs or completely impedes seed germination, and too much nitrogen can give crops a “burn.”

- The sector as a whole emits far lower CO2 per tonne of urea than the urea sector in the US or China.

- However, water consumption of Urea sector in India is high and can be reduced by at least one-third by using recycling/reuse technologies.

How to address the issues

- Indian agriculture needs to graduate from the present practice of bulk application of urea to a more precise supply of required nutrients.

- The industry needs to come up with new and innovative products to improve efficiency of nitrogen use from the current 30-35% to more than 60%. (Nano Urea could be a breakthrough)

- This will reduce urea consumption, improve soil health, increase yields and reduce N2O emissions.

- The production of nitrogen fertilisers will have to shift from fossil fuels to renewables.

Case Study

Fertilizer Corporation of India’s Nangal plant employed electrolysis of water to produce hydrogen until it switched to hydrocarbons in the 1970s due to shortage of power in the Bhakra grid.

So clearly, we have the technology to produce nitrogenous fertilisers without using fossil fuels.

- The falling costs of renewable energy will make this an economically feasible option.

- The system of subsidies and controls in its present form has led to imbalanced and gross overuse of urea with adverse consequences both for the environment and for agricultural productivity.

- Further, it neither benefits the small farmer nor does it support the industry adequately.

- The government needs to change its policy and bring a measure of decontrol Urea.

- Decontrol will make the industry competitive and bring innovations in production and products.

- The sector must go from being a volume driven industry which measures its performance by tonnes of urea produced, to a functionality driven industry which measures its performance by improved soil health and better yields.

Non-Urea Fertilisers

- The MRPs of non-urea fertilisers are decontrolled or fixed by the companies.

- The Central Govt, pays a per-tonne subsidy on these nutrients to ensure they are priced at “reasonable levels”.

- Examples of non-urea fertilisers: Di-Ammonium Phosphate (DAP), Muriate of Potash (MOP).

Indian Fertilizer Industry

- The Indian fertilizer industry can broadly be divided into two categories, depending on the nutrient composition:

- nitrogenous fertilizers and

- phosphatic and potassic (P&K) fertilizers.

- The overall fertilizer consumption in India has grown at a CAGR of 2.0% from 50.6 million t in FY2009 to 61.4 million t in FY2020.

https://www.pib.gov.in/PressReleasePage.aspx?PRID=1760014