Source: DownToEarth

Disclaimer: Copyright infringement not intended.

Context

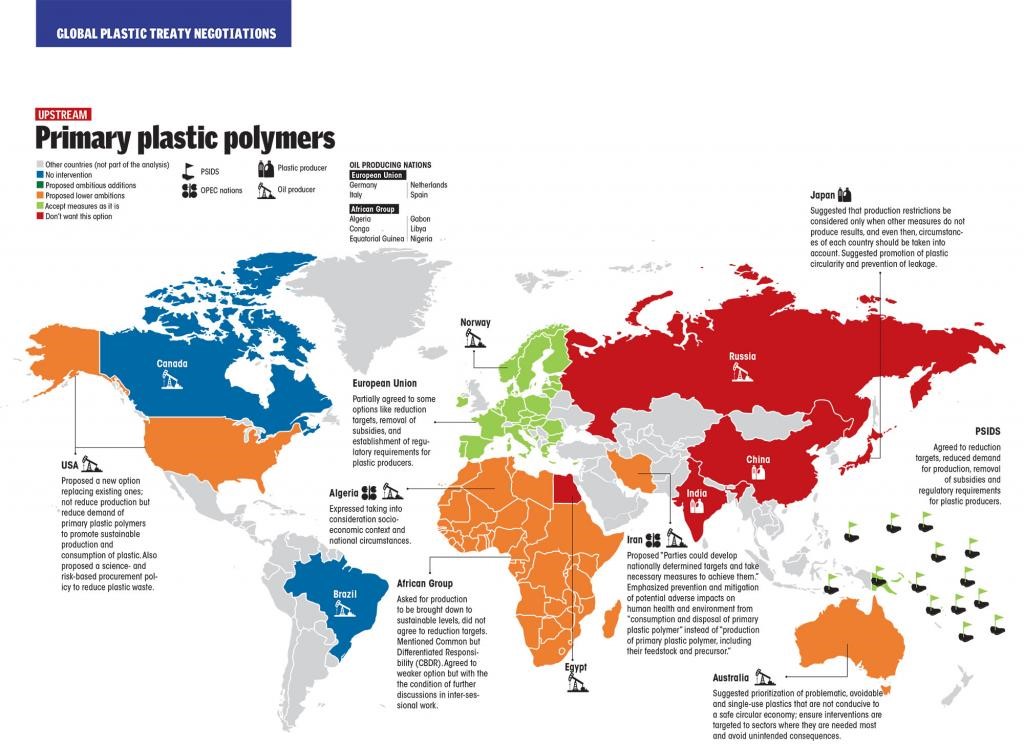

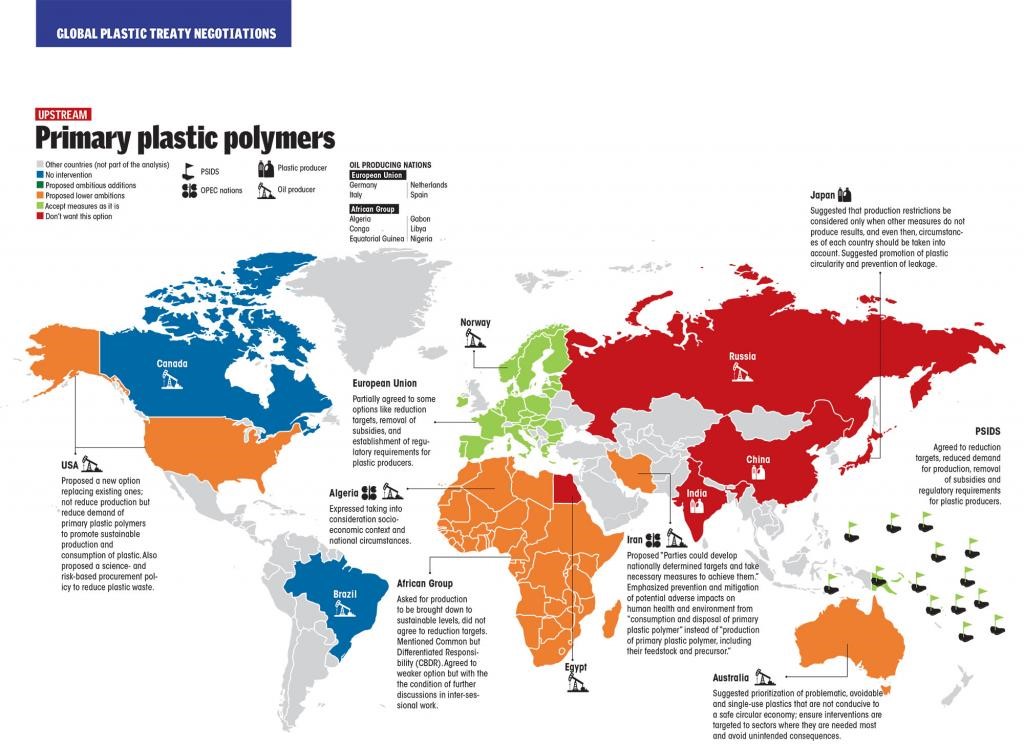

- In the context of the ongoing negotiations within the United Nations Environment Assembly (UNEA) to end plastic pollution, the term “primary plastic polymers” refers to the types of plastic resins or polymers that are commonly used in the production of plastic products.

- These primary polymers represent the foundational building blocks of most plastic items found in everyday use.

Details

Global Plastic Profiles: Regulation of Primary Polymers

Source: DownToEarth

Disclaimer: Copyright infringement not intended

Importance of Negotiations within UNEA:

- Targeted Measures: Negotiations focus on identifying primary polymers that contribute significantly to plastic pollution, enabling targeted regulatory measures.

- International Cooperation: By engaging in negotiations, countries collaborate to develop global strategies and agreements to tackle plastic pollution effectively.

- Policy Alignment: Negotiations help align national policies and regulations with international goals and commitments, fostering consistency and coherence in addressing plastic pollution.

- Capacity Building: Participation in negotiations provides opportunities for capacity building and sharing of best practices among countries, particularly those with limited resources or expertise.

About Primary Plastic Polymers

- Polymers are large molecules made up of repeating structural units, known as monomers.

- These molecules are formed through a process called polymerization, where monomers bond together to form long chains or networks.

- Primary plastic polymers are a subset of polymers that are widely used in various industries due to their versatile properties.

Classification of Primary Plastic Polymers:

Primary plastic polymers can be classified based on their chemical structure and properties. The main types include:

- Thermoplastics:

- These polymers can be melted and reshaped multiple times without undergoing any significant chemical change.

- Examples include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS).

- Thermosets:

- These polymers undergo irreversible chemical reactions during curing, forming a rigid three-dimensional network.

- Once cured, thermosets cannot be melted or reshaped.

- Examples include epoxy resins, phenolic resins, and polyester resins.

- Elastomers:

- These polymers exhibit elastic properties, returning to their original shape after being stretched.

- Examples include natural rubber, synthetic rubber (e.g., styrene-butadiene rubber, neoprene), and silicone rubber.

Properties and Applications:

Each primary plastic polymer exhibits unique properties, making them suitable for various applications:

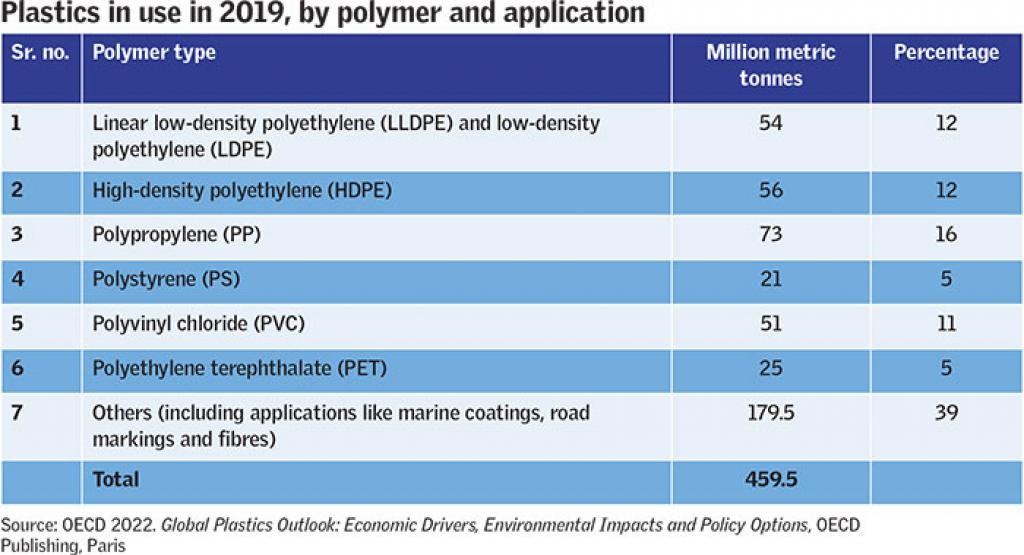

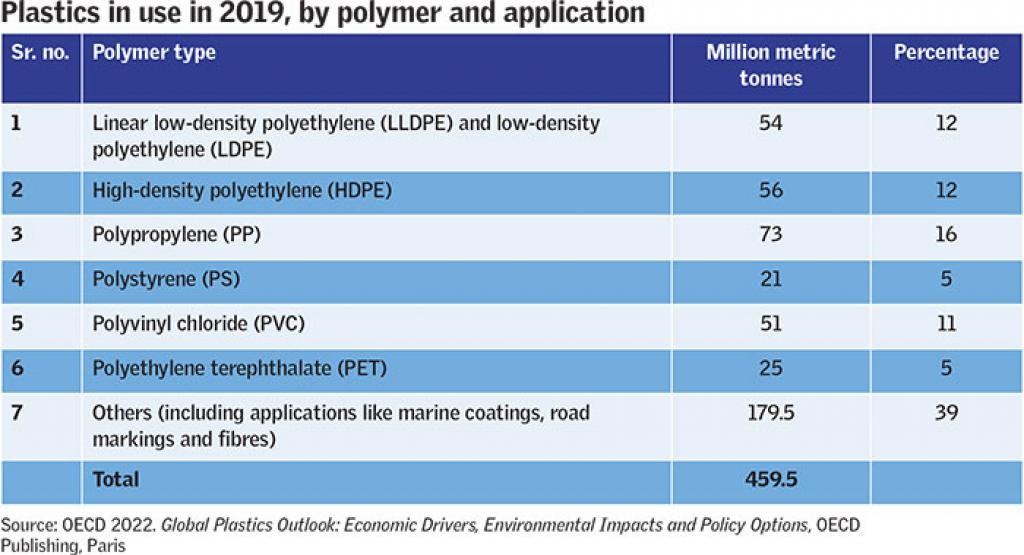

- Polyethylene (PE):

- Types: High-density polyethylene (HDPE), Low-density polyethylene (LDPE)

- Properties: Good chemical resistance, toughness, and flexibility.

- Applications: Packaging (e.g., bottles, bags), pipes, toys, and household products.

- Polypropylene (PP):

- Properties: High chemical resistance, stiffness, and heat resistance.

- Applications: Packaging, automotive parts, medical devices, and textiles.

- Polyvinyl Chloride (PVC):

- Properties: Good electrical insulation, chemical resistance, and flame retardancy.

- Applications: Construction (e.g., pipes, window frames), healthcare (e.g., IV bags), and consumer goods.

- Polystyrene (PS):

- Types: General purpose polystyrene (GPPS), High-impact polystyrene (HIPS)

- Properties: Transparency, rigidity, and thermal insulation.

- Applications: Packaging (e.g., foam cups, food containers), electronics, and disposable cutlery.

- Epoxy Resins:

- Properties: Excellent adhesion, chemical resistance, and mechanical strength.

- Applications: Coatings, adhesives, composites (e.g., in aerospace and automotive industries).

- Polyester Resins:

- Properties: High strength, weather resistance, and dimensional stability.

- Applications: Fiberglass reinforcement, boat building, automotive parts, and construction materials.

- Natural Rubber:

- Properties: High elasticity, resilience, and tear resistance.

- Applications: Tires, conveyor belts, footwear, and seals.

Source: DownToEarth

Disclaimer: Copyright infringement not intended

Environmental Considerations:

Despite their widespread use, primary plastic polymers pose environmental challenges due to their persistence in the environment and issues with disposal:

- Recycling: Many primary plastic polymers are recyclable, but challenges remain due to issues like contamination and lack of infrastructure.

- Biodegradability: Some biodegradable polymers are being developed as alternatives to traditional plastics, offering potential solutions to reduce environmental impact.

- Circular Economy Initiatives: Efforts are underway to promote a circular economy for plastics, emphasizing reuse, recycling, and responsible disposal practices.

About Plastics

- Plastics are a group of synthetic materials made from polymers, which are large molecules composed of repeating subunits called monomers.

- They are versatile materials that can be molded into various shapes, making them widely used in everyday products.

Types of Plastics:

Plastics can be categorized based on their chemical structure, properties, and applications:

- Thermoplastics: - These plastics can be heated and molded repeatedly without undergoing chemical change. - Examples: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS).

- Thermosetting Plastics: - These plastics undergo irreversible chemical changes when heated and molded, forming rigid structures. - Examples: Epoxy Resins, Phenolic Resins, Polyester Resins.

- Elastomers: - These are rubber-like materials that can return to their original shape after being stretched. - Examples: Natural Rubber, Synthetic Rubbers (e.g., Neoprene, Silicone Rubber).

Properties of Plastics:

Plastics exhibit a wide range of properties, including:

- Versatility: Plastics can be manufactured in various forms, from flexible films to rigid containers.

- Durability: Many plastics are resistant to chemicals, water, and weathering, making them suitable for outdoor applications.

- Lightweight: Plastics are generally lightweight, which can reduce transportation costs and energy consumption.

- Electrical Insulation: Certain plastics have excellent electrical insulating properties, making them ideal for electrical and electronic applications.

- Transparency: Some plastics, such as acrylic and polycarbonate, are transparent, allowing for optical clarity in applications like windows and lenses.

Applications of Plastics:

Plastics are used in numerous industries and applications, including:

- Packaging: Plastic films, bottles, containers, and wraps are commonly used for packaging food, beverages, and consumer goods.

- Construction: Plastics are used in pipes, insulation, flooring, roofing, and other building materials due to their durability and versatility.

- Automotive: Plastics are found in car interiors, exteriors, and under-the-hood components to reduce weight and improve fuel efficiency.

- Electronics: Plastics are used in casings, connectors, and insulation for electronic devices and components.

- Medical: Plastics are used in medical devices, packaging, implants, and equipment due to their biocompatibility and sterilizability.

- Textiles: Synthetic fibers like polyester, nylon, and acrylic are used in clothing, upholstery, and industrial textiles.

Environmental Impact:

Despite their benefits, plastics pose environmental challenges:

- Pollution: Plastics contribute to pollution on land and in water bodies, harming wildlife and ecosystems.

- Microplastics: Plastic debris breaks down into tiny particles called microplastics, which can be ingested by marine life and enter the food chain.

- Resource Depletion: Plastics are derived from fossil fuels, contributing to resource depletion and greenhouse gas emissions.

- Waste Management: Improper disposal of plastics leads to littering, landfill accumulation, and challenges in recycling and waste management.

Recognition of Chemicals and Polymers of Concern

- Definition: "Chemicals of concern" and "polymers of concern" refer to specific substances recognized for posing significant risks to human health and the environment throughout their life cycles.

- Examples: Chemicals of concern include additives like plasticizers (e.g., phthalates), flame retardants (e.g., brominated compounds), colorants, and stabilizers used in plastic manufacturing. Polymers of concern include certain plastics like expanded polystyrene (EPS) foam and specific types of polyvinyl chloride (PVC).

- Impact: These chemicals and polymers are known for their toxicity, persistence, and potential to bioaccumulate, posing risks during production, use, and disposal by leaching into the environment.

Negotiation Priorities:

- Identification and Regulation: Negotiations prioritize identifying and regulating chemicals of concern, promoting safer alternatives, and implementing measures to reduce exposure.

- Targeted Actions: Discussions aim to address challenges related to polymers of concern through targeted regulatory actions, innovation, and policy measures to mitigate the impacts of plastic production and disposal.

Proposed Approach:

- Negative and Positive Lists: One proposed approach involves creating a negative list of hazardous chemicals prohibited for use and a positive list of permissible chemicals subject to stringent testing requirements.

- Safeguarding Ecosystems and Public Health: By focusing on chemicals and polymers of concern, negotiations aim to safeguard ecosystems and public health from the detrimental effects associated with hazardous plastic materials.

- Promoting Sustainability: The overarching goal is to foster sustainability and innovation in plastic management practices, promoting the transition towards safer and more environmentally friendly alternatives.

Must read articles:

UNEP

Sources:

DownToEarth

|

PRACTICE QUESTION

Q. The regulation of primary plastic polymers is a critical aspect of global efforts to combat plastic pollution. Critically Analyse. (250 Words)

|