Disclaimer: Copyright infringement not intended.

Context

- In the backdrop of Semicon India 2022 being organised by Ministry of Electronics & IT stakeholders are exploring collaboration opportunities for promoting the semiconductor and electronics industry.

Semicon India 2022 Conference

- The conference is envisioned as the launch pad to kick start country’s ambition in becoming the global semiconductor hub and nurture the chip design and manufacturing ecosystem.

- The three-day conference, is being organised to take forward the vision to make India a leader in the electronics manufacturing , semiconductor design, manufacturing and innovation,.

- Eminent experts from industry associations, research organizations and academia will take part in this conference.

- They will deliberate upon policy, talent, government’s role and efforts in creating a favorable growth environment for the semiconductor ecosystem in the country.

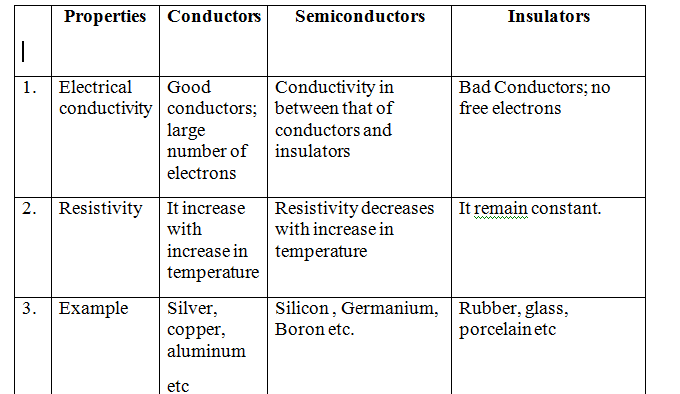

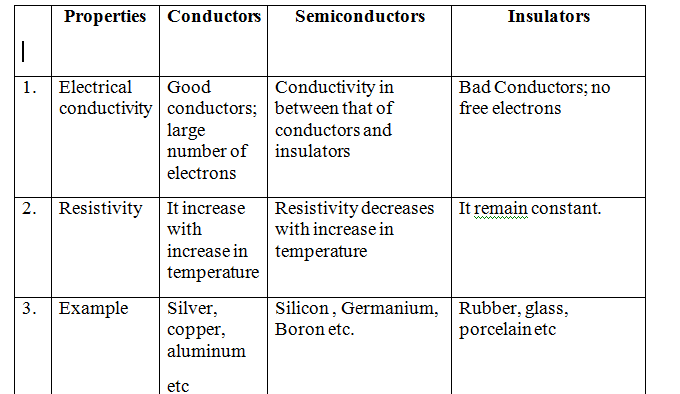

Semiconductor

- Semiconductors, or chips, have properties that are somewhere between conductors and insulators.

- Usually made of silicon, they are used to power a wide range of devices - cars, laptops, smart-phones, household appliances and gaming consoles.

- These tiny objects perform a host of functions such as powering displays and transferring data.

- So, a supply crunch has a consequent impact on sales of cars, fridges, laptops, TVs and other electronic devices.

Semiconductor Industry: Challenges specific to India

Competition

- It is difficult to compete with neighbouring countries like China and Vietnam which have been favourite destinations for global chip manufacturers due to better cost-efficiency.

Massive investment

- In addition to the huge cost, running in billions of dollars, manufacturing even a single chip requires hundreds of gallons of pure water, which may also be hard to find in India in the required quantities.

Infrastructure

- There have been challenges in setting up of Semiconductor Wafer Fabrication (FAB) units in India.

- India is still not unto the par in terms of the basic infrastructure needed.

Power Supply

- An uninterrupted power supply is another major hurdle.

- The heart of the issue is that India is still not unto the par in terms of the basic infrastructure needed to pursue endeavours in the chip manufacturing space.

Price pressure

- There is also constant price pressure from other global players, particularly China which is also building a homegrown chip program for the adoption of local semiconductors in 70% of its products by 2025.

Dependency on Imports

- India imports 100% of its semiconductors.

- Around 40 percent of India’s demand is met through imports from China, despite the frequent geopolitical impasse that the two nations find themselves in.

|

Global Giants

Taiwan holds a virtual monopoly in the global chip manufacturing industry.

The company is responsible for over half of all semiconductor chips that are manufactured in the world, and the country as a whole is responsible for over 60 percent of global production.

Other major centres include South Korea and the US.

|

Steps taken by the Government to boost Semiconductor Industry

Development of sustainable semiconductor and display ecosystem in the country Programme

- The comprehensive programme for the “development of sustainable semiconductor and display ecosystem in the country” is aimed at making India a global hub of electronic system design and manufacturing.

- The scheme would provide fiscal support of up to 50% of the project cost for setting up semiconductor and display fabrication units.

100% FDI in the ESDM

- In 2016, the government allows 100% FDI in the ESDM sector through an automatic route to attract investments including from Original Equipment Manufacturers (OEMs) and Integrated Device Manufacturers (IDMs).

Electronics development Fund

- The Department of Electronics and Information Technology (DeitY) has established an Electronics Development Fund (EDF) managed by Canara Bank to provide risk capital and to attract venture funds, angel funds and seed funds for incubating R&D and fostering the innovative environment in the sector.

Initiatives under Telecom and Electronic Policies

- Some of the initiatives outlined in the National Electronics policy and the National Telecom policy are in the process of implementation, such as Preferential Market Access (PMS), Electronics Manufacturing Clusters (EMC) and Modified Special Incentive Package Scheme (M-SIPS).

Scheme for Promotion of manufacturing of Electronic Components and Semiconductors (SPECS)

- Ministry of Electronics and Information Technology (MeITy) has drawn up the Scheme for Promotion of manufacturing of Electronic Components and Semiconductors (SPECS).

Production-linked incentive scheme (PLI) scheme

- Under the scheme, the Centre will offer financial support to companies that want to manufacture a range of semiconductor goods in India.

- The subsidy will bring down the production costs of companies manufacturing such goods, and thus encourage them to set up new factories and other facilities.

India Semiconductor Mission

- India Semiconductor Mission (ISM) has been setup as an Independent Business Division within Digital India Corporation.

- The Corporation has administrative and financial autonomy to formulate and drive India’s long term strategies for developing semiconductors and display manufacturing facilities and semiconductor design ecosystem.

- ISM will serve as the nodal agency for efficient, coherent and smooth implementation of the schemes.

Sub-schemes:

Following four schemes have been introduced under the India Semiconductor Mission (ISM):

- Scheme for setting up of Semiconductor Fabs in India

- It provides fiscal support to eligible applicants for setting up of Semiconductor Fabs which is aimed at attracting large investments for setting up semiconductor wafer fabrication facilities in the country.

|

Semiconductor fab

A semiconductor fab is a manufacturing plant in which raw silicon wafers are turned into integrated circuits.

A fab lab features a clean room where the environment is controlled to eliminate dust and vibration and keep the temperature and humidity within a narrow range. In the clean room, the integrated circuits are etched onto wafers through photolithography, a process that involves photographing the circuit pattern on a photosensitive substrate and chemically etching away the background. The completed chips are sent to a back-end assembly and test facility.

|

- Scheme for setting up of Display Fabs in India

- It provides fiscal support to eligible applicants for setting up of Display Fabs which is aimed at attracting large investments for setting up TFT LCD / AMOLED based display fabrication facilities in the country.

- The Scheme provides fiscal support of up to 50% of Project Cost subject to a ceiling of INR 12,000 crore per Fab.

- Scheme for setting up of Compound Semiconductors / Silicon Photonics / Sensors Fab and Semiconductor Assembly, Testing, Marking and Packaging (ATMP) / OSAT facilities in India:

- The Scheme provides a fiscal support of 30% of the Capital Expenditure to the eligible applicants for setting up of Compound Semiconductors / Silicon Photonics (SiPh) / Sensors (including MEMS) Fab and Semiconductor ATMP / OSAT facilities in India.

- Design Linked Incentive (DLI) Scheme

- It offers financial incentives, design infrastructure support across various stages of development and deployment of semiconductor design for Integrated Circuits (ICs), Chipsets, System on Chips (SoCs), Systems & IP Cores and semiconductor linked design.

- The scheme provides “Product Design Linked Incentive” of up to 50% of the eligible expenditure subject to a ceiling of Rs 15 Crore per application and “Deployment Linked Incentive” of 6% to 4% of net sales turnover over 5 years subject to a ceiling of Rs 30 Crore per application.

Way Ahead

- As 5G mobile networks proliferate with many people working from home, the need for more powerful, energy-efficient chips is only going to grow.

- The rise of artificial intelligence is another force pushing innovation, since AI relies on massive data processing.

- Indian semiconductor industry is set for a stable upsurge with bright prospects provided India's generic obstacles like redtape-ism, fund crunch and infrastructural deficits are adequately addressed.

- Steps needed to be taken:

- Land Acquisition by the government: acquire the land and develop a special economic zone (SEZ) which would encompass a complete semiconductor manufacturing ecosystem.

- Cover all ancillaries: The monetary benefits being extended for setting up a fab should be made available for all the ancillary units manufacturing specialty chemicals to clean room apparel.

- Focus on simple technology: The requirements are less stringent and the fabs less expensive. These companies typically operate at much lower gross margins as opposed to the large fabs and Original Equipment Manufacturer (OEMs).

- With the implementation of fabrication capabilities in India, the country could achieve a degree of self-sufficiency in the sector of semiconductors.

- Building a strong semiconductor industry would put an end to the country’s reliance on imports to meet its semiconductor needs and will help in the creation of jobs.

https://www.pib.gov.in/PressReleasePage.aspx?PRID=1821561